The Future of Laser Processing: Innovations in Cutting, Marking, and Welding

Understanding Laser Processing Innovations

Laser processing involves using concentrated laser energy to cut, engrave, or mark a variety of materials, offering exceptional versatility across numerous industries, including manufacturing and aerospace. This method utilizes highly focused beams of light to carry a substantial amount of energy, making it suitable for precision tasks and a wide range of applications like cutting and engraving. Notably, it has become integral in industries like manufacturing, where it is used for intricate tasks such as welding, marking, and laser engraving. The application of laser techniques not only enhances manufacturing precision but also improves the quality of finished products across diverse sectors, from automotive to electronics.

The relevance of innovation in laser processing is increasing as advancements drive efficiency, precision, and cost reduction in production processes. Recent industry trends and research reports highlight significant productivity improvements due to technological advancements in laser systems. For instance, the global laser processing market is projected to surpass USD 44.09 billion by 2032, reflecting a growing demand for innovative solutions. Innovations, such as the introduction of fiber and diode lasers, have significantly enhanced the speed and quality of laser processing, allowing industries to optimize their operations and reduce wastage. Consequently, these advancements have enabled industries to meet the high standards required for modern precision manufacturing, demonstrating the vital role of innovation in expanding the capabilities of laser processing.

Innovations in Laser Cutting Techniques

Recent advancements in laser cutting technology have significantly enhanced its capabilities, offering improved performance and efficiency. Higher wattage lasers are a notable development, enabling faster cutting speeds and improved material handling. These advancements facilitate precise and clean cuts across various materials, reducing production time and increasing output quality. High-power lasers with innovative architectures are setting new standards in both the performance and reliability of laser cutting machines.

A comparative analysis between traditional cutting methods and laser cutting reveals several advantages of the latter. Unlike conventional methods, laser cutting significantly reduces waste, as its precision minimizes excess material removal. Additionally, it effortlessly handles complex shapes and intricate designs that would be challenging or impossible with manual cutting tools or mechanical saws. Laser technology ensures a contact-free process, eliminating the risk of tool wear and tear and the need for frequent maintenance. This cleanliness and reduced waste contribute to more sustainable and cost-effective manufacturing, illustrating why industries are increasingly adopting laser cutting solutions over traditional alternatives.

Innovations in Laser Marking Applications

Innovations in laser marking technologies have significantly broadened the scope of applications across various industries. Key advancements involve the use of CO2, fiber, and solid-state lasers, each offering unique benefits for specific tasks. CO2 lasers work particularly well for non-metal materials like wood and acrylic due to their longer wavelengths. Fiber lasers, on the other hand, excel in marking metals and plastics thanks to their high electrical efficiency and long service life. Solid-state lasers find a niche in applications requiring high precision, such as electronic components.

The benefits of laser marking are substantial, underscoring its growing adoption in industry. Notably, laser marking is lauded for its durability and precision. It can create marks that withstand harsh environments, which is critical for applications in the automotive and aerospace sectors. The process is also eco-friendly, as it doesn't involve consumables like ink or chemicals. According to studies, laser-marked products boast an impressive lifespan, with quality holding steady over time. Furthermore, laser marking's ability to produce clear, permanent marks with minimal waste aligns with sustainability goals.

Innovations in Laser Welding Processes

Recent advancements in laser welding technologies have revolutionized the field, especially with the integration of hybrid welding techniques and automation. Hybrid welding combines the benefits of different welding technologies, such as traditional methods with laser welding, resulting in increased welding speeds and enhanced quality. Automation in laser welding not only improves precision but also significantly reduces production times, making these processes more efficient and reliable. The use of robotics in laser welding processes further ensures consistency and allows for complex welding patterns that were previously challenging.

These innovations are transforming industries by dramatically enhancing joint quality and expanding the range of materials that can be efficiently joined. The precise and controlled nature of laser welding makes it possible to work with materials like thin metals and intricate components that are difficult to handle using conventional welding methods. Industries such as automotive, aerospace, and electronics are leveraging these improvements to achieve stronger, more durable joints with minimal heat distortion. As a result, laser welder machines are becoming indispensable in manufacturing settings where precision and reliability are crucial, underscoring the essential role of laser technology in contemporary production landscapes.

Featured Laser Processing Products

Explore cutting-edge laser processing solutions designed to meet diverse industrial needs. Each machine offers unique capabilities, ensuring high performance and versatility.

- Laser Engraving and Cutting Machine 1530: This machine stands out with its superior power and precision, ideal for large-format cutting. With an expansive working area of 1500x3000mm, it handles tasks requiring high speed and precision effortlessly. Its robust features, including high-quality laser tubes and Ruida high-performance motherboard, enhance reliability and output consistency. Ideal for industries like manufacturing and design, it supports a range of software tools such as CAD and AI, ensuring seamless integration into existing workflows.

- Laser Engraving and Cutting Machine 3020: Tailored for space-conscious environments, the 3020 model ensures precision in small-scale projects with its compact design. It features a high-quality laser tube with a longer lifespan, and is equipped with a Ruida high-performance motherboard, ensuring functionalities like power-off engraving and enhanced accuracy. It is perfect for detailed design tasks where space and precision are critical, making it a preferred choice for small workshops and art studios.

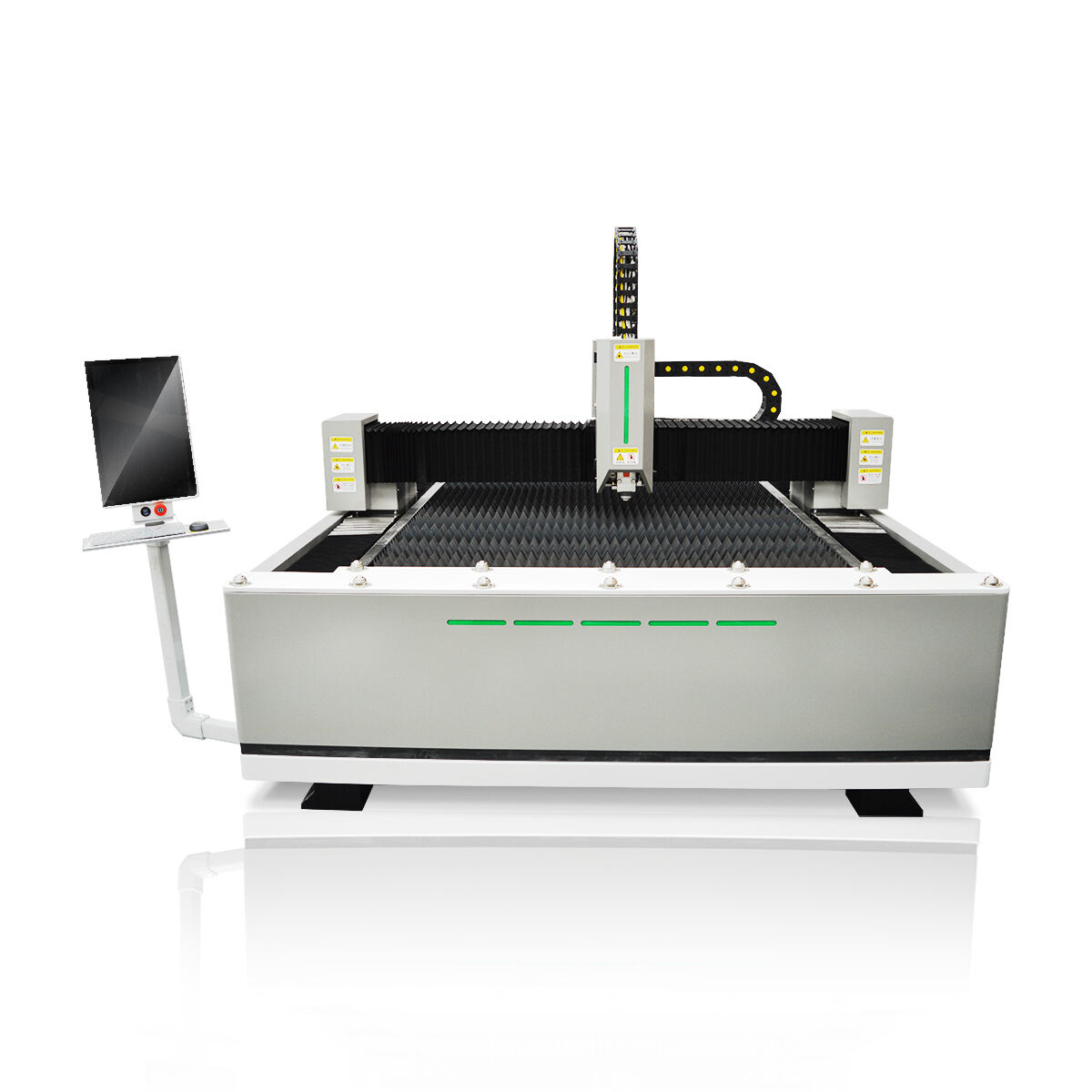

- Fiber Laser Cutting Machine 1530: This model offers unrivaled precision and speed, crucial for modern industrial applications. It's equipped with a fiber laser system that consumes minimal energy, optimizing operational costs. Capable of cutting an array of metals with high efficiency, this machine meets the demands for rapid production cycles without compromising on quality. It's ideal for sectors like automotive and aerospace, where material versatility and precision are imperative.

These innovative laser processing machines are tailored to enhance productivity, offering solutions for a range of industrial applications.

Future Trends in Laser Processing

Emerging technologies in laser processing are shaping the future landscape significantly. One of the prominent advancements includes integrating advanced materials and artificial intelligence (AI) into laser processing systems. These technologies enable more precise control and efficiency, which can revolutionize applications such as laser welding machines and laser engraving machines. AI, in particular, enhances performance by optimizing processes in real-time, reducing human error, and increasing productivity. This fusion of technologies is expected to broaden the scope of laser applications, making them indispensable in industries like aerospace and healthcare.

Market forecasts reveal a bright future for laser processing, driven by continuous innovation and technological growth. The global laser processing market is expected to grow significantly, with estimates projecting a rise from USD 22.27 billion in 2023 to over USD 44.09 billion by 2032. This growth is attributed to the increasing demand for precision and efficiency, particularly in regions like Asia-Pacific, which dominated the market share with advanced laser technologies. Expert opinions suggest that innovations, such as improved laser engraver machines and laser cleaning machines, will continue to propel this sector forward, creating extensive opportunities for businesses and consumers alike.