Achieving High-Precision Results with Advanced Laser Engraving and Marking Solutions

Understanding High-Precision Laser Engraving and Marking

Laser engraving involves deploying focused laser beams to etch or mark various materials. This robust method is noted for its precision and versatility, making it ideal for industries requiring intricate designs and detailed markings. Whether it's metals like aluminum or steel, or other materials like plastics and glass, laser engraving machines deliver unparalleled results by vaporizing material with pinpoint accuracy. This process allows for the creation of permanent and highly detailed designs without physically contacting the surface, ensuring there is minimal wear and tear on the materials used.

The benefits of high-precision laser engraving are significant. It allows for the production of complex designs with remarkable detail, improving the aesthetic and functional features of items across different industries. Moreover, the capability to mark a diverse range of materials ensures that it can be applied to various sectors, from automotive to manufacturing. Using advanced laser engrave machines, this process is fast and efficient, reducing material waste and operational costs. The non-contact nature of the process ensures maximum speed and minimizes material distortion, making it a go-to choice for businesses aiming for efficiency and precision.

Key Technologies in Laser Engraving and Marking Solutions

In the realm of laser engraving and marking, various laser types cater to different applications, each with unique capabilities and advantages. CO2 lasers, for instance, are highly effective in working with organic materials such as wood, paper, and certain plastics. Their ability to cut and engrave with precision makes them suitable for artistic and craftwork applications. On the other hand, fiber lasers excel in metal marking and engraving due to their high power and efficiency. They are especially favored in industries requiring detailed and durable engravings like the automotive and aerospace sectors. Recently, UV lasers have emerged, offering cleaner, finer engravings suitable for delicate materials and applications like electronics and medical devices. This diversity in laser types ensures that there is a specific technology tailored for each industry requirement.

Modern laser engraving machines are enhanced by advanced features that significantly improve their functionality and efficiency. Among these are Computer Numerical Control (CNC) systems, which allow for precise control of complex engravings and markings through programmed software. Integrated software solutions streamline operations, offering user-friendly interfaces and customization options for various projects. Additionally, the support for automation in laser engraver machines facilitates seamless integration into manufacturing lines, increasing productivity and consistency in large-scale operations. These features not only augment the capabilities of laser engravers but also make them accessible and versatile tools for both small-scale and industrial applications.

Applications of High-Precision Laser Engraving and Marking Solutions

High-precision laser engraving and marking solutions are extensively utilized across a multitude of industries due to their capabilities in ensuring traceability, branding, and customization. Key sectors include manufacturing, where laser marking helps maintain product traceability, and healthcare, which demands precision for compliance with regulations on medical devices. In the consumer goods sector, lasers are used to brand products with logos and labels prominently. The aerospace and automotive industries also employ these technologies for labeling parts with precision and permanence, ensuring safety and performance.

Specific use cases further highlight the versatility of laser engraving and marking machines. For example, in the medical field, lasers are used to mark devices with unique identifiers essential for compliance with stringent regulations. In the consumer market, laser engravers personalize jewelry and gifts, adding individual touches like names or messages. Promotional items frequently feature laser-engraved logos, showcasing branding in a durable format. These examples underscore how laser technologies, such as laser engraving machines or laser engrave machines, adapt to various materials and requirements, offering both functionality and aesthetic appeal.

Top Products for High-Precision Laser Engraving and Marking Solutions

Laser Engraving and Cutting Machine 1325

The Laser Engraving and Cutting Machine 1325 is engineered for excellence in large-scale production environments. This machine stands out with its dual-motor X-axis/Y-axis setup and precision-focused optical path design. It features fast curve continuous cutting capabilities powered by high-quality laser tubes and a stable Ruida high-performance motherboard. This hardware ensures consistent laser power output across the worktable, making it ideal for industries requiring large-format cutting. Additional options for rotary carving accessories extend its versatility to include cylindrical and irregular products.

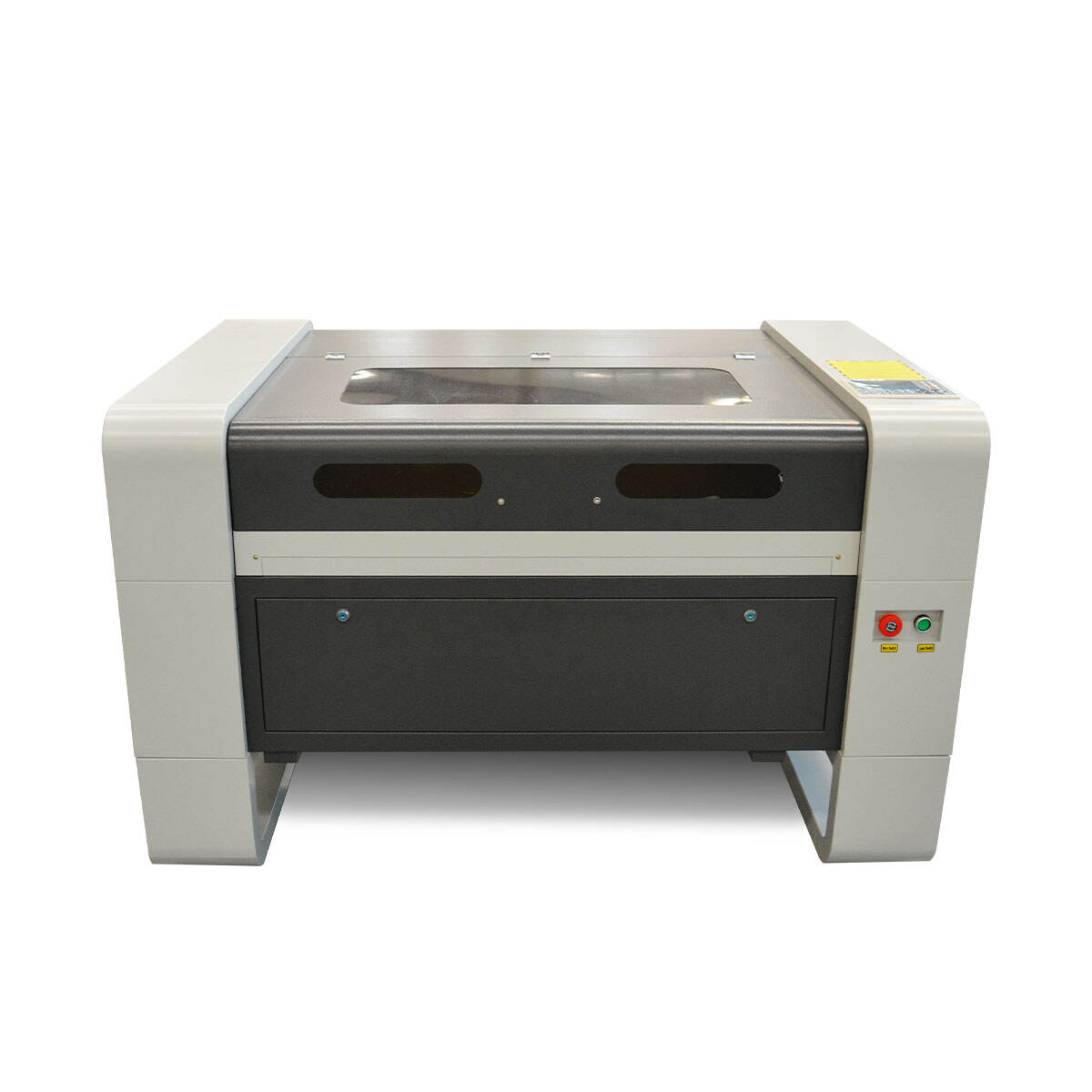

Laser Engraving and Cutting Machine 9060

The Laser Engraving and Cutting Machine 9060 provides precision and efficiency tailored for small to medium-sized projects. Equipped with a professional carved optical lens and electric lift platform, this machine excels in detailed engraving tasks and accommodates varying material thicknesses. High-performance components such as imported Taiwan linear guide rails ensure smooth operation and longevity, making it highly suitable for intricate work in industries like jewelry creation and promotional item manufacturing. Its user-friendly interface and strong software compatibility further simplify operations in customized engraving projects.

Split Type Laser Marking Machine

The Split Type Laser Marking Machine offers an innovative design for seamless integration into existing production lines. Known for its fast engraving speed and compact body, it is lightweight and consumes low power, making it suitable for high-speed marking tasks. Its air-cooled system reduces energy consumption while maintaining stable performance, even under challenging environmental conditions. This machine virtually eliminates downtime also enabling consistent operation, making it perfect for businesses aiming for mass production with precision and efficiency.

Benefits of Investing in High-Precision Laser Solutions

Investing in high-precision laser solutions offers significant cost-effectiveness and sustainability benefits. Laser engraving technology, compared to traditional methods, significantly reduces material waste through its precise and accurate processing capabilities. It also lowers operational costs by minimizing the need for consumables and offering superior energy efficiency. For instance, unlike older mechanical methods, laser systems create precise, intricate designs without the need for physical contact, reducing tool wear and the associated replacement costs.

The long-term benefits for manufacturers embracing laser technology are profound. Improved product quality and precision result in reduced labor costs, as the need for skilled manual interference is minimized. This enables manufacturers to enhance their competitive edge in the market. Industry research highlights that the shift towards laser systems supports increased operational efficiency and productivity, contributing to a substantial return on investment. With laser solutions, manufacturers can stay ahead of the curve, maintaining high standards and meeting the demands of an ever-evolving market landscape.

prehensive utilization of laser technologies.

Future Trends in Laser Engraving and Marking Technology

Emerging advancements in laser engraving and marking technology continue to transform the manufacturing industry. Innovations such as integrating artificial intelligence improve the precision and efficiency of laser engraver machines. AI can enhance processing speed and reduce errors, allowing more intricate designs and patterns to be produced. Moreover, laser cleaning machines are also being refined for better speed and operational efficiency, ensuring quicker turnaround times for manufacturers.

The market for high-precision laser solutions is set to grow significantly over the coming years. According to recent forecasts, the Industrial Laser Marking Machine market is projected to reach USD 6.41 billion by 2032, reflecting a strong CAGR of 8.1% from 2024 to 2032. This growth is driven by increasing adoption across various sectors such as automotive, electronics, and aerospace, where the demand for permanent and precise marking solutions is rising. As industries shift towards more automated and efficient processes, the role of laser welding machines and engrave machines will likely expand, helping businesses meet ever-evolving quality and regulatory standards.