What Are the Key Benefits of CO₂ Laser Marking Machines in High-Precision Applications?

Understanding CO₂ Laser Marking Machines

CO₂ laser marking machines are advanced tools that utilize carbon dioxide as a laser medium for precise marking applications. These machines are integral to various industries due to their ability to produce permanent, high-quality marks on different materials by using a focused laser beam. The principle of laser marking revolves around the interaction of a laser beam with the material surface, causing engraving or ablation that results in permanent marks. This process involves transferring the laser's energy into heat to alter the surface’s structure or appearance, which is highly effective in creating durable and clear marks.

CO₂ laser marking is commonly used in several fields, notably manufacturing, healthcare, and packaging, due to its versatility and efficiency. In manufacturing, it is ideal for marking materials like glass, ceramics, and various plastics. In healthcare, CO₂ lasers contribute to traceability through marking surgical instruments. In the packaging sector, these machines ensure products are readily identifiable with barcodes or expiry dates, enhancing supply chain efficiency. The widespread application across these fields demonstrates the CO₂ laser marking machine's essential role in modern industrial processes.

Key Advantages of CO₂ Laser Marking Machines in High-Precision Applications

CO₂ laser marking machines excel in high-precision applications, providing significantly greater accuracy compared to traditional marking methods. These advanced laser engraving machines can achieve up to 10 times more precision, making them an ideal choice for industries where intricate details and clear markings are vital. The high accuracy of CO₂ lasers ensures that even the most delicate designs are executed with perfection, showcasing the power of laser engraving machinery in delivering exceptional results.

The versatility of CO₂ laser marking machines allows them to be utilized across a wide range of materials. They are adept at marking on plastics, wood, glass, and metals, which broadens their applicability across various industries, from manufacturing to healthcare. This adaptability is one of the reasons why CO₂ laser engraver machines have become an essential tool in promoting efficiency and quality in product marking and branding.

In addition to precision and material versatility, CO₂ laser marking machines are renowned for their speed and efficiency. Many models are capable of reducing processing time significantly, with some achieving up to 30% faster marking speeds. This rapid performance translates into higher productivity, allowing businesses to meet tight deadlines without compromising on quality.

Moreover, CO₂ laser marking machines boast durability and low maintenance requirements. The robust design involves fewer moving parts, which not only enhances their longevity but also reduces operational costs. For businesses, this means less downtime and lower expenses related to part replacements or repairs, thus optimizing operational efficiency.

Environmentally friendly alternatives are increasingly sought after, and CO₂ laser technology meets this demand by consuming less energy and producing minimal waste. Unlike ink-based marking solutions, CO₂ lasers ensure a cleaner and more sustainable production process. This eco-friendly aspect aligns with contemporary business practices that emphasize sustainability, making CO₂ laser marking machines a conscientious choice for companies aiming to reduce their environmental footprint.

Applications of CO₂ Laser Marking Machines in High-Precision Industries

CO₂ laser marking machines play a crucial role in the automotive sector by significantly enhancing part identification and traceability. These machines enable the precise marking of parts, which is essential for maintaining rigorous quality control standards. In a market characterized by increasing demand for eco-friendly, non-contact marking solutions, the precision offered by laser marking is invaluable. This technology helps prevent counterfeit parts, thus safeguarding both manufacturers and consumers.

In manufacturing, CO₂ laser marking machines aid in maintaining product traceability. They facilitate clear and permanent marking that complies with industry regulations, assisting firms in adhering to strict labeling norms. Moreover, by enhancing product authenticity, brands can maintain integrity and consumer trust. The ability to mark varied materials, such as metals, plastics, and ceramics, makes these machines an asset for industries focused on diverse production lines.

Laboratories also benefit from the precision of CO₂ laser marking machines, especially in research where custom-designed tools and equipment are critical. For instance, laser marking is used to create detailed scales or labels on laboratory instruments, which is essential for precise measurements. The reliability of laser engraver machines ensures that critical markings remain legible and intact over time, supporting the rigorous demands of scientific research environments. Precision and consistency in marking are indispensable in such settings, where even minute discrepancies can impact research outcomes.

Key Benefits of CO₂ Laser Marking Machines in High-Precision Applications

CO₂ laser marking machines stand out in the field of high-precision applications due to their material versatility and cost-effectiveness compared to other laser technologies like fiber and UV lasers. While fiber lasers offer superior precision and longer lifecycles, CO₂ lasers excel in handling a diverse range of materials, including non-metallic surfaces such as wood, glass, and ceramics. This versatility makes them a more economical choice for industries that require flexibility in material processing, allowing businesses to maintain competitive pricing while ensuring quality output.

Moreover, CO₂ laser marking machines are well-integrated with industry standards, which is crucial for meeting the stringent requirements of various certifications. Adhering to these standards not only supports market competitiveness but also ensures compliance with essential regulations across different sectors. From automotive to consumer electronics, these machines help businesses achieve their branding, compliance, and traceability goals, thus securing product authenticity and enhancing the company's market position.

Lastly, the impact of CO₂ laser marking machines on production workflow and cost efficiency is significant. By providing precise and reliable marks, these machines minimize errors and waste, leading to a smoother production process. According to some industry experts, companies have observed up to a 25% reduction in errors and waste, enhancing overall operational efficiency and driving cost savings. This efficiency is pivotal for maintaining high standards of quality while reducing overhead, making CO₂ laser machines a valuable asset in today's competitive market landscape.

Top CO₂ Laser Marking Machines for High-Precision Applications

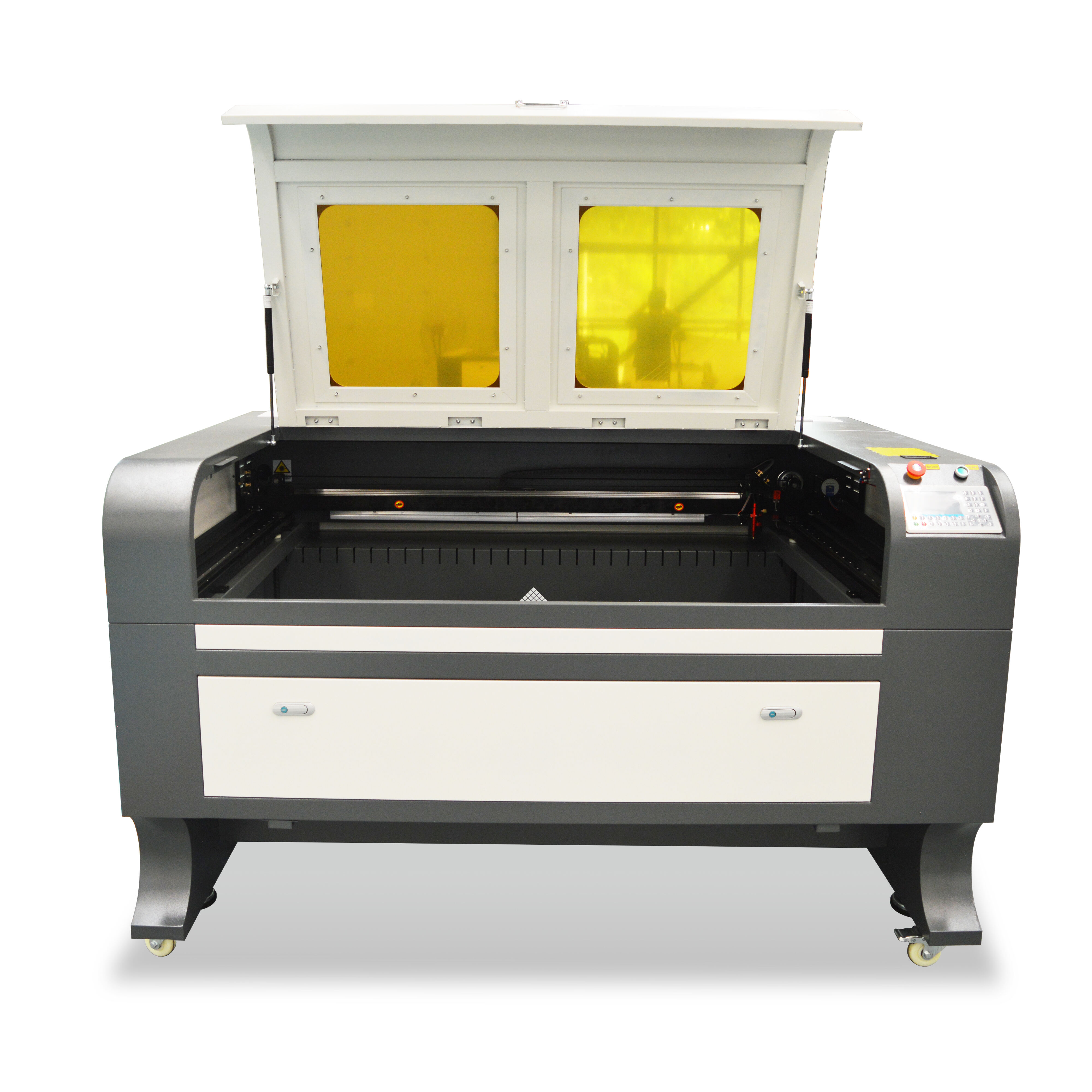

In the realm of high-precision applications, CO₂ laser marking machines stand out for their exceptional accuracy and versatility. Among the top contenders are the Laser Engraving and Cutting Machine 1310, Laser Engraving and Cutting Machine 1390, and the Cabinet Type Laser Marking Machine. These machines are designed to meet diverse industrial needs, offering enhanced features and robust capabilities.

- Laser Engraving and Cutting Machine 1310: Known for its precision and efficiency, this machine utilizes professional carved optical lenses and red light positioning to ensure accurate results. It supports various materials, making it versatile for both engraving and cutting tasks. Learn more about the Laser Engraving and Cutting Machine 1310.

- Laser Engraving and Cutting Machine 1390: This model is slightly smaller but maintains high performance with similar advanced features, ensuring stability and efficiency in cutting and engraving applications. Discover more about the Laser Engraving and Cutting Machine 1390.

- Cabinet Type Laser Marking Machine: Featuring a compact design ideal for diverse industrial applications, this machine offers stable power output, excellent beam quality, and high marking speeds. It is particularly effective for projects demanding depth and precision. Explore the Cabinet Type Laser Marking Machine.