The Versatility of CO2 Laser Engraving Machines for Different Materials

Understanding CO2 Laser Engraving Machines

CO2 laser engraving is a modern technology that uses carbon dioxide gas as a medium to create a high-intensity laser beam. This process involves generating a powerful and focused infrared laser beam by stimulating a gas mixture primarily made up of carbon dioxide, nitrogen, and helium. This type of laser is ideal for cutting, marking, or engraving a vast range of non-metallic materials. Originally developed by Kumar Patel in 1964, CO2 lasers remain popular due to their power, precision, and versatility, capable of producing intricate designs and precise cuts across various materials.

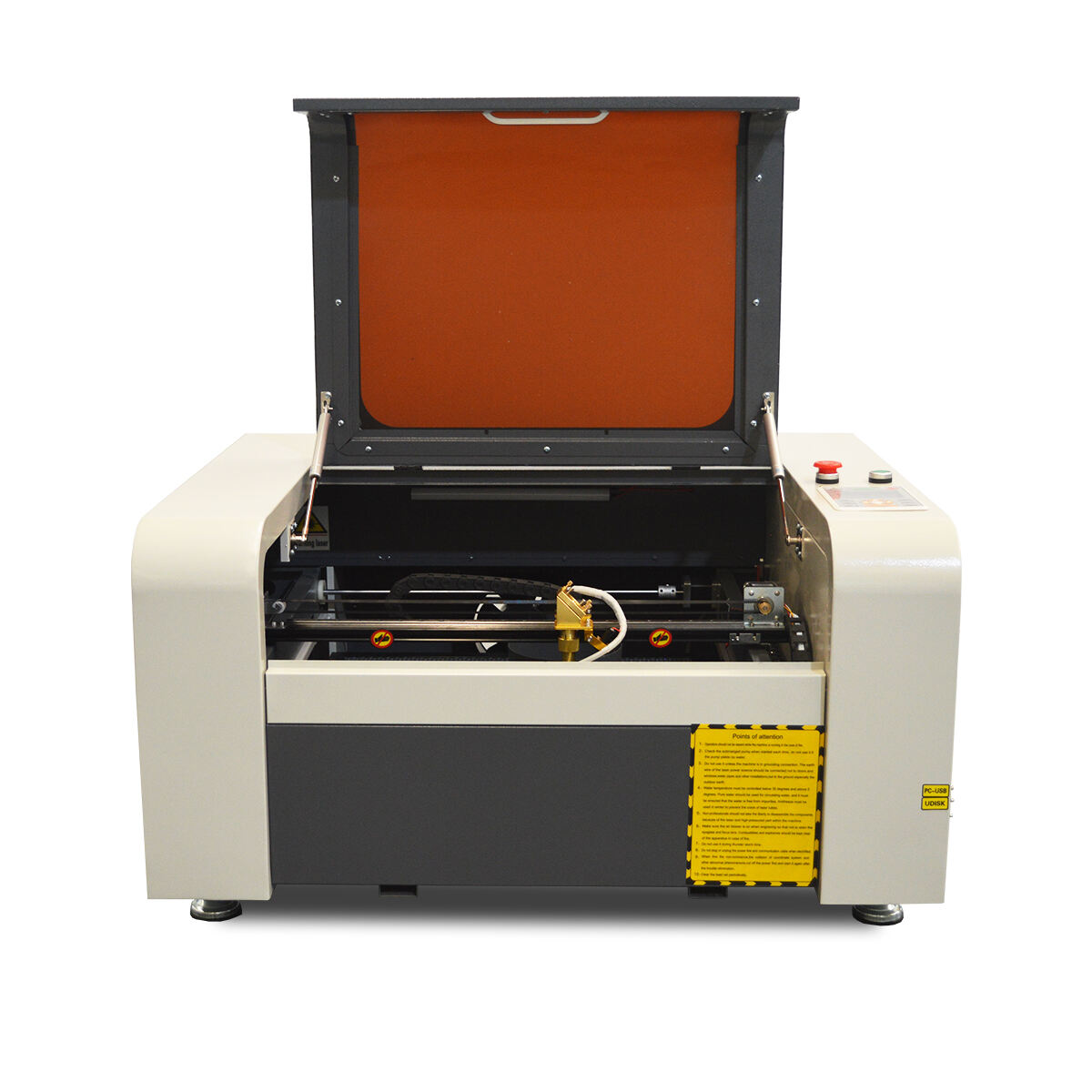

The mechanism of CO2 laser engravers relies on a series of processes, from power generation to the final engraving. First, the laser beam is produced within a glass or metal tube by electrically stimulating the CO2 gas mixture. This beam is then guided to the target surface using a series of mirrors and lenses, which focus the beam to a precise point capable of vaporizing or melting the surface material. Controlled by computer software, the laser head or material moves according to digital patterns, enabling precise etching or cutting. This entire process is efficient and allows for detailed and abrasion-resistant engravings, making CO2 laser engravers a vital tool in numerous industries.

Applications of CO2 Laser Engraving

CO2 laser engraving machines are widely used across various industries due to their precision and versatility. In the industrial sector, these machines are indispensable in manufacturing, packaging, and signage. They can create precise cuts and engravings on materials like metal, plastic, and wood, tailoring products for specific industry requirements. For instance, CO2 lasers are commonly used to produce detailed signage, customized packaging, and intricate designs for automotive parts, enhancing both functionality and aesthetic appeal.

Artists and crafters utilize CO2 laser engravers extensively for creative projects and crafts. These devices offer unparalleled precision, allowing for detailed artwork and intricate designs that would be challenging to achieve manually. From personalized gifts and home decor to elaborate art pieces, the creative possibilities are virtually endless. For example, artists can laser-engrave their designs onto wood or acrylic to create unique, customized pieces that stand out in any collection or display.

The demand for personalization and customization is on the rise, and CO2 laser engraving meets this consumer trend perfectly. With an increasing desire for bespoke items, consumers seek products that reflect their personal style. CO2 laser engraving allows businesses to offer customized items, such as engraved jewelry, personalized gadgets, and bespoke homeware. This not only adds value to the products but also caters to the modern consumer’s preference for unique and individualized items.

Advantages of Using CO2 Laser Engraving

CO2 laser engraving is recognized for its unparalleled precision and accuracy. These engravers use focused laser beams to achieve high-precision results, ensuring minimal material waste and superior product quality. The precision aspect is critical in industries requiring intricate detailing and complex patterns, such as electronics or jewelry manufacturing, where accuracy is paramount to the product's success.

The versatility of CO2 laser engraving across multiple materials makes it an invaluable tool in various industries. Typical materials compatible with CO2 laser engravers include wood, acrylic, leather, and glass. Each of these materials has distinct applications: wood is used extensively in crafting and construction; acrylic finds its place in signage and display; leather is prominent in fashion and interior design; and glass is utilized in decorative and functional settings such as customized glassware.

Another key advantage of CO2 laser engraving is its non-contact processing nature, reducing the risk of damage to workpieces. This is especially beneficial when working with delicate materials that require careful handling. The lack of physical contact means there's less wear and tear on the material, maintaining its quality and longevity. Moreover, non-contact processing allows for consistent results even in complex designs, further enhancing the appeal of CO2 laser engraving in various creative and industrial applications.

Top CO2 Laser Engraving Machines Available

Choosing the right CO2 laser engraving machine can make a significant difference in your production capabilities. Here's a closer look at some top models in the market today:

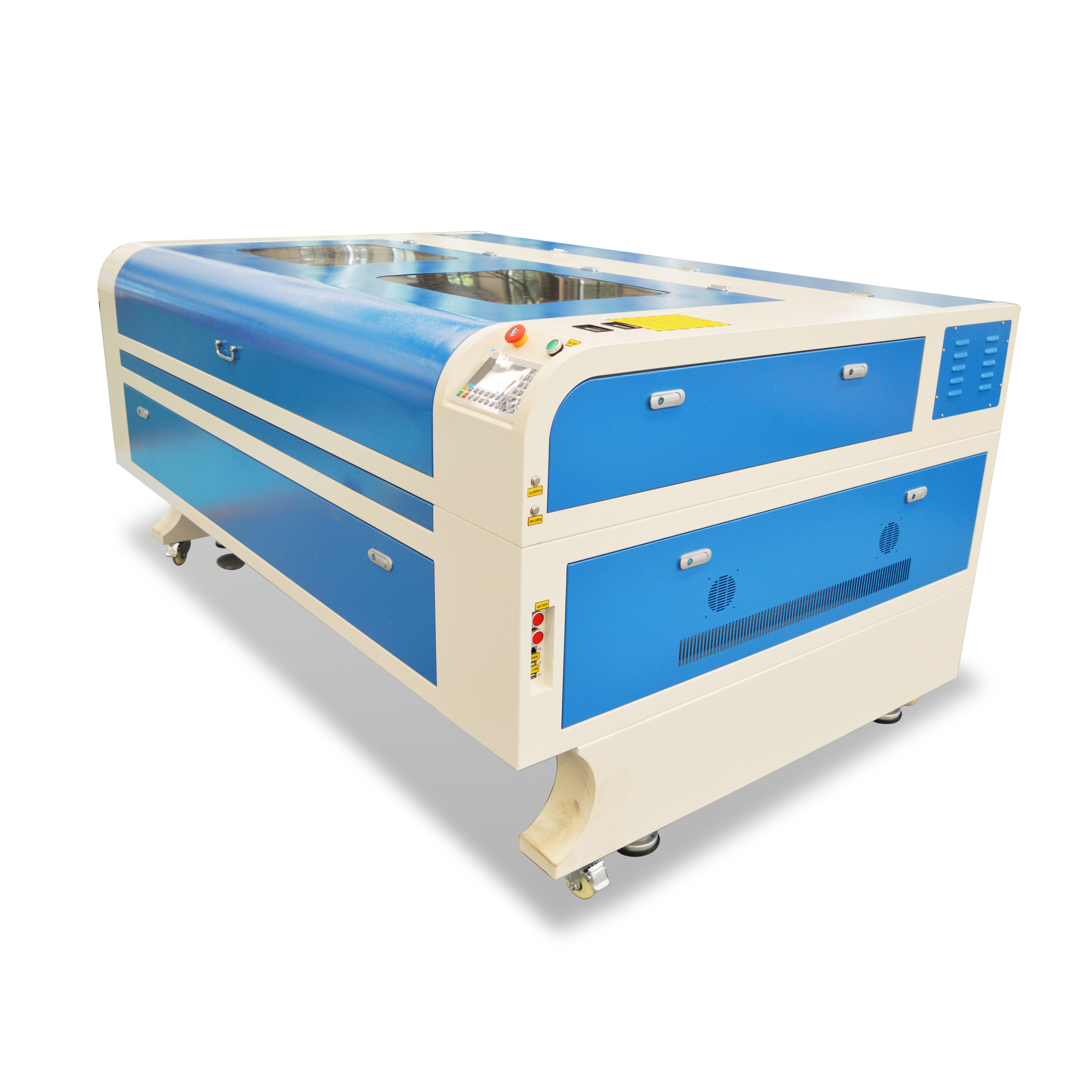

- Laser Engraving and Cutting Machine 1530: This machine is equipped with high-quality laser tubes and a Ruida high-performance motherboard that ensures stability and accurate output. It features a large working area, ideal for big projects, and a maximum engraving speed of 1024mm/s. Its unique capability, such as an optional rotary carving accessory, allows engraving on cylindrical items, making it highly versatile for different materials and shapes.

- Laser Engraving and Cutting Machine 1610: Designed with an automatic feeding platform, this machine is perfect for larger-scale operations. Its extensive capabilities include a dual laser head system offering flexibility in operation. The advanced DSP control technology significantly enhances cutting efficiency and precision, making it suitable for sheet metal and other materials needing intricate detailing.

- Laser Engraving and Cutting Machine 3020: This model is aimed at both industrial users and creative sectors. Its compact footprint and powerful yet precise operation make it an excellent choice for business environments with space constraints or for intricate artistic applications. It balances industrial-grade performance with creative flexibility.

- Laser Engraving and Cutting Machine 4040: Targeted at users needing a balance between space and functionality, this machine offers a compact design without compromising on quality or performance. Its integrated red light positioning and cellular lifting platform cater to precision tasks even in confined workshop environments, ideal for SMEs and hobbyists.

- Laser Engraving and Cutting Machine 4060: Popular among professionals, this model combines efficiency with ease of use. Featured with a robust design capable of handling various materials and complex shapes, its operational efficiency is backed by user reviews praising its performance in diverse applications, making it favored in professional settings.

These machines cater to a variety of needs from detailed artistry to large-scale industrial applications, promising efficiency, precision, and versatility essential for high-quality engraving projects.

Choosing the Right CO2 Laser Engraving Machine

Selecting the ideal CO2 laser engraving machine involves considering several critical factors. Power specifications are paramount as they determine the machine’s capability to cut through various materials. The bed size is another crucial factor, influencing the size of materials that can be engraved or cut. Software compatibility is also essential, as it determines the efficiency and effectiveness of the machine’s operation, impacting project outcomes.

In today's market, certain brands and models stand out due to their market reputation and performance. Leading names such as DXTECH are renowned for their high-quality and innovative CO2 laser engraving machines. Popular models from these brands are often preferred due to their reliable performance, advanced features, and excellent after-sales service. Evaluating these factors ensures that you choose a machine that aligns with your specific project needs and business goals.

Maintenance and Safety Tips for CO2 Laser Engraving Machines

Routine maintenance is vital for ensuring the longevity and efficiency of CO2 laser engraving machines. Essential tasks include regular lens cleaning, which prevents damage caused by accumulated debris and dust. Calibration should be performed periodically to maintain the machine's precision and accuracy. Additionally, inspecting and replacing worn parts, like belts and bearings, can prevent unexpected breakdowns. Keeping a maintenance schedule and recording each activity performed can significantly enhance machine performance over time.

Safety precautions are crucial when operating CO2 laser engravers to prevent accidents. Operators should always wear protective eyewear specifically designed for laser use to shield their eyes from potentially harmful rays. Ensuring proper ventilation in the workspace is equally important, as it prevents the inhalation of fumes and gases released during engraving. Additionally, never leave the machine unattended while it's running, and always have an emergency shutdown procedure in place. By adhering to these safety measures, you can ensure a secure working environment while operating laser engraving machines.

Conclusion: Enhancing Craftsmanship with CO2 Laser Engraving Machines

CO2 laser engraving machines have revolutionized craftsmanship across various industries by blending precision with innovation. These powerful tools allow professionals and hobbyists alike to add intricate details and personal touches to their work, enhancing creativity and elevating product quality. The versatility of CO2 laser technology extends to multiple materials, from wood and glass to metals, making it an essential asset in today’s competitive market. We encourage you to explore this advanced technology to elevate your creative and professional projects to new heights.