The Role of Laser Engraving in Creating Detailed and Intricate Patterns

Understanding Laser Engraving: An Innovative Technique

Laser engraving is a cutting-edge process that employs focused laser beams to permanently engrave a variety of materials. This technique, known for its precision and efficiency, involves using lasers to vaporize the surface of materials such as metal, wood, glass, and plastic, leaving behind a permanent mark. Laser engraving allows for intricate designs and detailed artworks, making it an invaluable tool in both artistic and industrial applications.

The popularity of laser engraving can be attributed to its remarkable precision, speed, and versatility. Unlike traditional methods, laser engraving offers unparalleled accuracy, capable of producing complex patterns with high fidelity. It is also incredibly fast, suitable for both small-scale and large-scale projects, which enhances productivity in industries ranging from manufacturing to personalized gift creation. Additionally, its versatility across various materials broadens its appeal, making laser engraving a preferred choice for sectors seeking diverse and customized solutions.

Key Benefits of Laser Engraving for Intricate Designs

Laser engraving offers remarkable precision and detail in crafting intricate patterns. This precision is achieved through laser beams that can focus on extremely small spots, allowing for detailed designs on complex surfaces. For instance, a project requiring delicate floral patterns on wood can achieve exceptional detail, enhancing the aesthetic appeal of the finished product. The ability to engrave with such precision makes laser engraving a preferred choice in industries where accuracy is paramount.

In addition to precision, laser engraving is highly versatile, capable of working across a wide range of materials including wood, glass, metal, and acrylic. According to industry statistics, laser technology can successfully engrave on nearly 80% of common industrial materials, making it a versatile tool in manufacturing, art, and design. This compatibility allows businesses to use laser engraving for a variety of projects, from creating custom gifts to marking industrial components.

The efficiency and speed of laser engraving further underscore its benefits. Advanced laser systems can complete tasks rapidly, significantly reducing production times compared to traditional methods. A case study from a manufacturing firm revealed that laser engraving reduced their marking time by over 30%, resulting in increased operational efficiency and cost savings. This rapid processing capability makes laser engraving an optimal solution for both large-scale industrial applications and individual design projects.

Applications of Laser Engraving in Various Industries

Laser engraving has become a staple in producing custom gifts and personalized items, driven by a robust growth in market demand. According to recent statistics, the global market for personalized gifts is expected to reach $38 billion by 2027. This growth underscores the popularity of laser-engraved items like personalized jewelry, bespoke home décor, and custom awards, which cater to consumers' desire for unique, tailored products.

In industrial and commercial settings, laser engraving offers unparalleled precision for manufacturing parts. This precision is crucial for industries like aerospace and automotive, where even minor inaccuracies can lead to significant performance issues. The ability to engrave intricate details makes laser engraving an essential tool for labeling parts, creating barcodes, and adding logos—all vital for product identification and traceability.

The role of laser engraving in art and craftsmanship cannot be overstated. Artists utilize laser engravers to bring their creative visions to life on various materials, from wood and glass to metal and acrylic. For instance, renowned artist Michael Boswell uses laser engraving to create his signature wood sculptures that emphasize intricate patterns and details. This technique allows artists to achieve exceptional levels of detail that would be difficult to replicate manually, opening up new possibilities in the art world.

Getting Started with Your Laser Engraver Machine

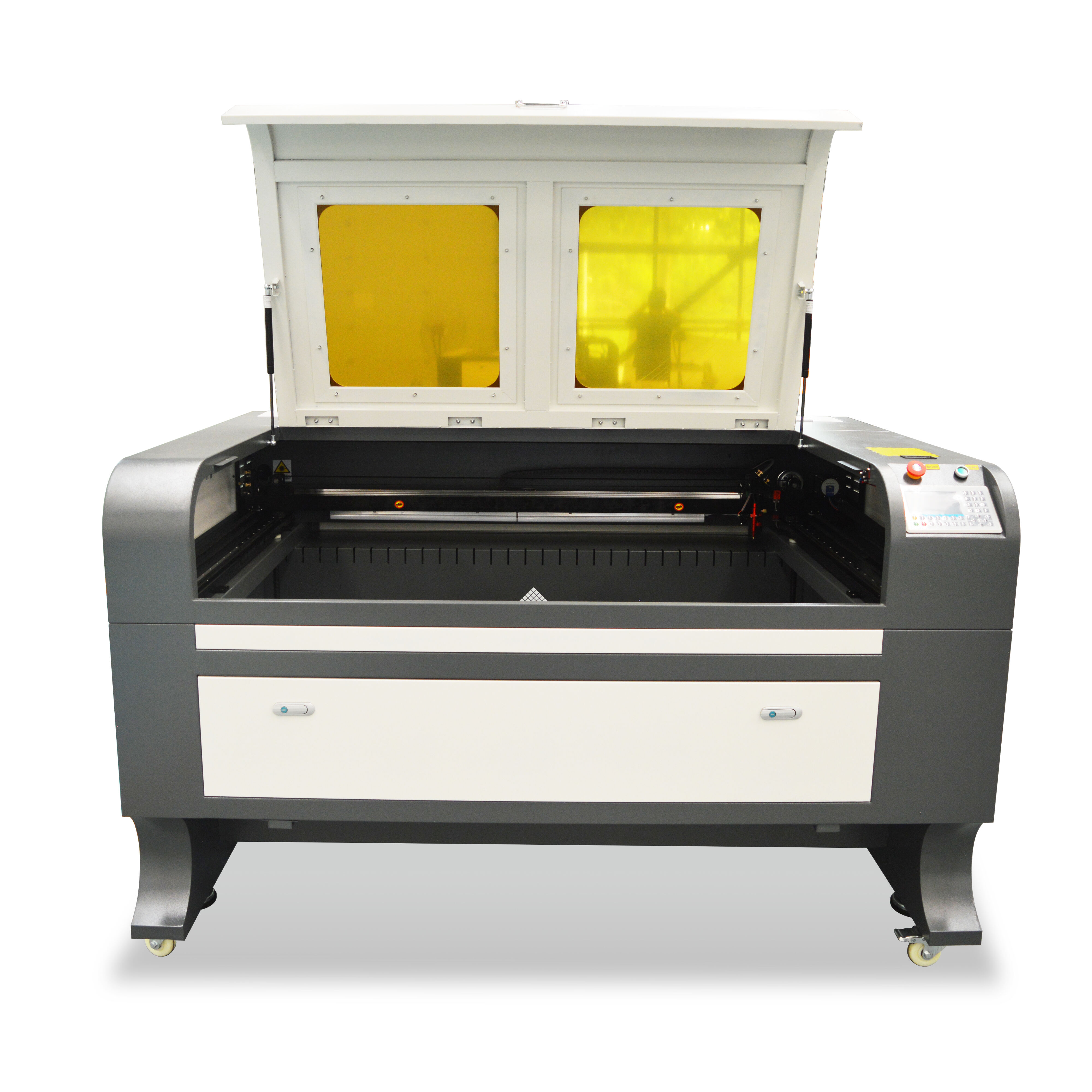

Introducing the Laser Engraving and Cutting Machine 1310, ideal for precision projects. This model is renowned for its high-quality optical lenses and laser tubes, ensuring consistent light stability. Featuring a positioning red light and a lift platform capable of reaching 200mm, the machine offers excellent versatility. Its compatibility with various software makes it perfect for the gold plating industry and for handling cylindrical and irregular products.

The Laser Engraving and Cutting Machine 1390 is another robust model, known for its flexibility and excellence in both small and large tasks. With a similar setup to the 1310 model, it facilitates precision with red light positioning and features a significant working area of 1300mm x 900mm. Its strong software compatibility also allows users to manage comprehensive data output efficiently.

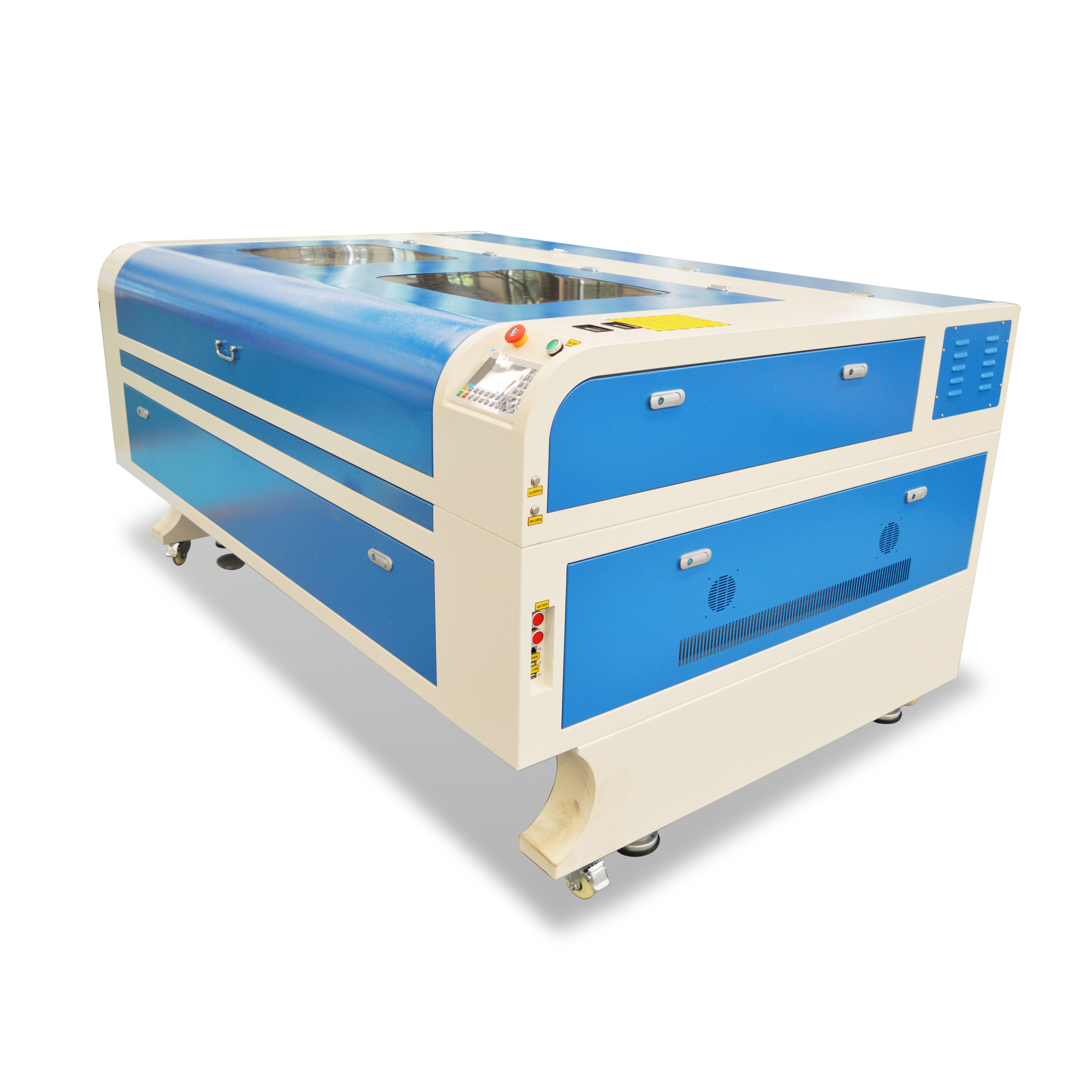

For those tackling larger projects, the Laser Engraving and Cutting Machine 1530 is your go-to. It combines an extensive 1500mm x 3000mm workspace with dual motor X-axis/Y-axis systems for swift and continuous cutting. This machine's offline functionality enhances productivity for mass manufacturing.

The Laser Engraving and Cutting Machine 1610 stands out with its precise DSP control technology and automatic feeding platform, enhancing efficiency and minimizing deviations. Its versatility, with dual laser heads that can be adjusted for different task demands, makes it a preferred choice for detailed and complex work.

Lastly, the Laser Engraving and Cutting Machine 3020 offers a compact and user-friendly interface, making it a favorite for intricate tasks. Its robust software compatibility, combined with ease of manual adjustments, makes it incredibly efficient for high precision projects.

These machines offer a range of capabilities, each tailored to different scales and complexities of laser engraving projects, ensuring there's an option for every demand and skill level.

Choosing the Right Laser Engraver for Your Needs

Selecting the right laser engraver requires considering several key factors to meet your specific needs. First, assess the power of the laser, as it determines the types of materials you can work with and the depth of engraving. Next, evaluate the bed size of the machine which will dictate the maximum size of materials you can process. Lastly, focus on any extra features, such as rotary attachments for cylindrical objects or advanced software capabilities that can enhance your project versatility.

There are various types of laser engraving machines, each suited to different applications. CO2 lasers are commonly used for non-metal materials like wood and plastic, perfect for crafting and prototyping. Fiber lasers, on the other hand, excel in metal engraving, offering precision and speed for industrial applications. UV lasers are reserved for delicate materials due to their cold marking capabilities, ideal for electronics. For hobbyists, diode lasers provide an affordable option, though they are less powerful and better suited for softer materials.

When considering costs and budget, it's important to understand the price ranges for different machines. Basic diode lasers accessed by hobbyists may start at a few hundred dollars, while more powerful CO2 and fiber lasers, which cater to professional needs, typically range from a few thousand to tens of thousands of dollars. Maintenance costs, the availability of spare parts, and operational expenses are also factors to factor into your budget. By weighing these elements, you can select a laser engraver that aligns with both your application requirements and financial constraints.

Tips for Designing Intricate Patterns with Laser Engraving

Creating intricate patterns through laser engraving requires a keen understanding of vector design. Vector designs provide the cleanest results due to their scalability without loss of detail. When creating these designs, ensure that the lines are clear and the curves smooth to reduce the likelihood of errors during the engraving process. Use software like Adobe Illustrator or CorelDRAW, which are popular among professionals for their precision and design capabilities.

Understanding material compatibility is crucial for design success and longevity. Not all materials react the same way to laser engraving. For example, wood may char and produce a darker color, while metals like anodized aluminum result in a frosty-white finish. Always consult material-specific guidelines to ensure that your design aligns with the material's properties. This consideration is vital for maintaining both the aesthetic quality of the design and the integrity of the material.

Key settings adjustments are essential to achieve optimal results. The most critical settings include power, speed, and frequency, typically adjusted in that order. Power determines how deep or aggressively the laser will engrave, while speed affects the engraving duration and detail clarity. Lastly, frequency involves the pulse rate of the laser, influencing the smoothness of the engraving. Start with a test engraving to fine-tune these settings, ensuring the final product meets your expectations without any material damage.

Maintaining Your Laser Engraving Machine for Longevity

To ensure your laser engraving machine remains in prime working condition, regular maintenance is crucial. Begin with a simple cleaning protocol: remove debris from the engraving surface and air vents to prevent overheating and ensure laser precision. Lubricate moving parts and inspect them for wear and tear regularly. Additionally, check the machine's optics; a microfiber cloth can be used to clean lenses gently. Keep a maintenance log to track and schedule these tasks to align with manufacturer recommendations.

Common issues with laser engravers can include misalignment or inconsistent laser output. Troubleshooting these often starts with recalibrating the machine according to the user manual or checking for obstructions. If problems persist, consult the manufacturer's support for guidance. Basic troubleshooting skills can help resolve issues before major disruptions occur, maintaining production efficiency.

Regular software updates are just as important for machine longevity. Software updates often include bug fixes, performance improvements, and new features, ensuring your machine runs efficiently and effectively. Staying current with updates can also improve compatibility with newer materials and design software, preventing potential operational issues. By incorporating these maintenance strategies, you can extend the lifespan and enhance the performance of your laser engraving machine.