The 1610 laser engraving machine is used for cutting and engraving non-metallic materials, and can be equipped with an automatic feeding device, making it more convenient and efficient to work.

Equipped with an automatic feeding platform, it ensures no deviation, strong pressure resistance, and saves labor. Adopting the most advanced DSP control technology, industry-leading continuous and fast curve cutting function, and shortest machining path optimization function, the work efficiency has been improved. Adopting a machine tool level stable and solid frame to ensure stability and accuracy during rapid operation. The transmission system adopts imported linear guide rails and precision gears to ensure machining accuracy. The processing requirements for large format cutting and opening have been achieved, meeting the processing needs of various conventional types of sheet metal. The dual laser heads can be designed with mutual displacement, and the distance between the laser heads can be freely adjusted and switched between single and dual excitation heads. Multi document function: can store up to 256 job files, and can still select files for mass production in offline mode.

|

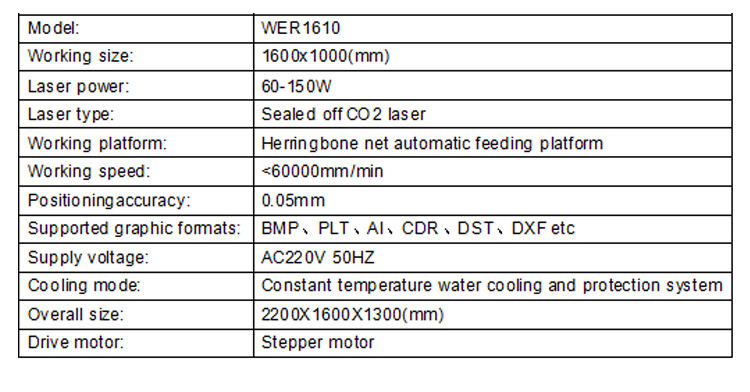

Model: |

WER1610 |

|

Working size: |

1600x1000(mm) |

|

Laser power: |

60-150W |

|

Laser type: |

Sealed off CO2 laser |

|

Working platform: |

Herringbone net automatic feeding platform |

|

Working speed: |

<60000mm/min |

|

Positioningaccuracy: |

0.05mm |

|

Supported graphic formats: |

BMP、PLT、Al、CDR、DST、DXF etc |

|

Supply voltage: |

AC220V 50HZ |

|

Cooling mode: |

Constant temperature water cooling and protection system |

|

Overall size: |

2200X1600X1300(mm) |

|

Drive motor: |

Stepper motor |