Fiber laser cutting machine uses laser technology for processing, mainly used in fields such as metal processing and inorganic non-metallic material processing. Compared with traditional mechanical processing techniques, fiber laser cutting machines have advantages such as fast processing speed, high accuracy, and high efficiency.

1.Ultra-low cost. Laser consumes only 0.5-1.5 KW per hour and the power of the whole machine is 7-9 KW.

2.High pressure air can be used to cut various metal sheets to reduce cutting costs.

3.High performance, imported original packaging fiber laser, stable performance, service life of more than 100,000 hours;

4. High speed and high efficiency. The cutting speed of sheet metal can reach more than ten meters per minute.

5. The cutting edge is good in quality, small in deformation, smooth in exterior light and beautiful in appearance.

6. Imported high precision guide rail, fine grinding rack drive and servo motor, fast cutting speed, high cutting accuracy;

7. All kinds of graphics or words can be designed at will to be cut instantly. The operation is simple, flexible and convenient.

|

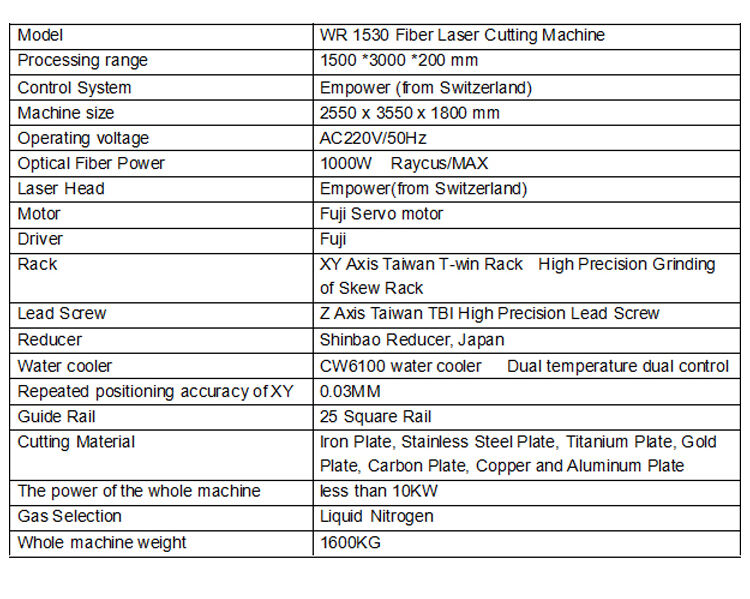

Model |

WR 1530 Fiber Laser Cutting Machine |

|

Processing range |

1500 *3000 *200 mm |

|

Control System |

Empower (from Switzerland) |

|

Machine size |

2550 x 3550 x 1800 mm |

|

Operating voltage |

AC220V/50Hz |

|

Optical Fiber Power |

1000W Raycus/MAX |

|

Laser Head |

Empower(from Switzerland) |

|

Motor |

Fuji Servo motor |

|

Driver |

Fuji |

|

Rack |

XY Axis Taiwan T-win Rack High Precision Grinding of Skew Rack |

|

Lead Screw |

Z Axis Taiwan TBI High Precision Lead Screw |

|

Reducer |

Shinbao Reducer, Japan |

|

Water cooler |

CW6100 water cooler Dual temperature dual control |

|

Repeated positioning accuracy of XY |

0.03MM |

|

Guide Rail |

25 Square Rail |

|

Cutting Material |

Iron Plate, Stainless Steel Plate, Titanium Plate, Gold Plate, Carbon Plate, Copper and Aluminum Plate |

|

The power of the whole machine |

less than 10KW |

|

Gas Selection |

Liquid Nitrogen |

|

Whole machine weight |

1600KG |