Exploring the Versatile Applications of Industrial Laser Cutting Machines

The core advantage of laser cutting machines is the non-contact processing method, which enables them to perform precise cutting without damaging the material. Whether it is metal sheets or non-metallic materials such as plastics and wood, laser cutting machines can provide high-quality cutting results. In addition, laser cutting machines also have the characteristics of fast cutting speed, good edge quality, and small deformation, which greatly improves production efficiency and product quality.

In the field of automobile manufacturing, laser cutting machines are used for precision processing of body parts, such as cutting of doors, roofs and other parts. These parts require extremely high dimensional accuracy and surface quality, and laser cutting machines can perfectly meet these requirements. In the field of aerospace, laser cutting machines are used to manufacture complex structural parts of aircraft, such as engine blades and fuselage skins. These parts often need to work in extreme environments, so they have extremely high requirements for material performance and processing accuracy. Laser cutting machines shine in this field with their high precision and high stability.

In addition to traditional manufacturing, laser cutting machines have also shown great potential in artistic creation and personalized customization. Artists use laser cutting machines to create unique patterns and shapes on a variety of materials, adding new dimensions to artworks. At the same time, laser cutting machines are also widely used in the production of jewelry, creating unique jewelry works through precise cutting and engraving.

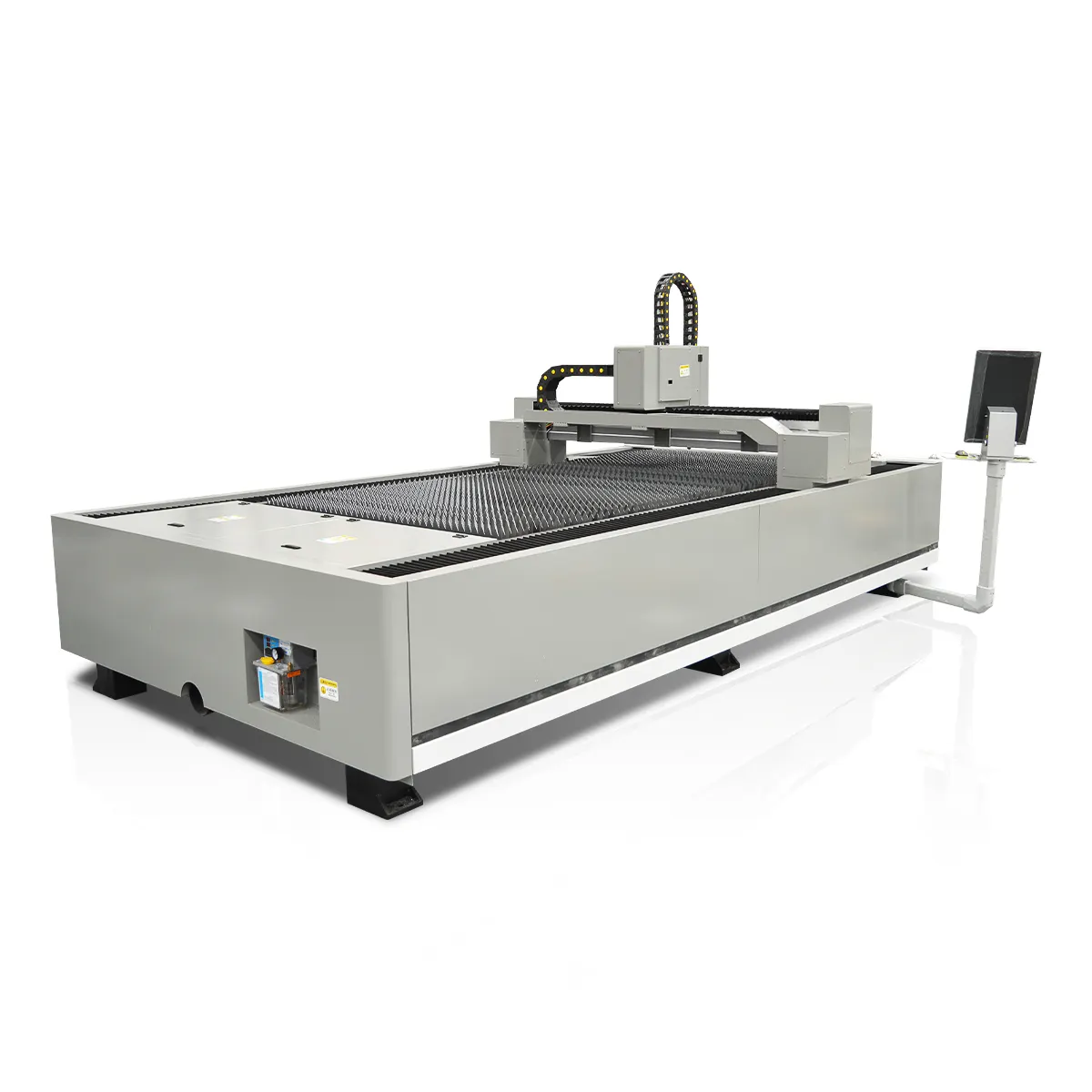

VOLERN's fiber laser cutting machine is a high-performance device that uses advanced fiber lasers and has the advantages of fast cutting speed, high cutting quality and low operating costs. Our machines are suitable for cutting metal sheets of various thicknesses and are ideal for the metal processing industry. VOLERN's desktop laser marking machine is a small and flexible device suitable for marking and engraving small workpieces, such as electronic components, medical devices, etc. It is easy to operate and has low maintenance costs, making it very suitable for application scenarios where the marking content needs to be changed frequently.