Innovative Trends in Laser Engraving Technology for Modern Manufacturing

Exploring the Latest Trends in Laser Engraving Technology for Manufacturing

The shift towards automated laser engraving systems is a pivotal trend in the manufacturing sector. These systems enhance productivity by minimizing human intervention, thus reducing human error significantly. By leveraging automation, manufacturers can achieve increased precision and repeatability in their engraving processes, which translates to higher quality outputs and cost efficiency.

The integration of Artificial Intelligence (AI) in laser engraving is another transformative trend. AI technologies are now being utilized to optimize engraving patterns and improve the quality of outputs. Smart engraving machines equipped with AI can automatically adjust settings to best suit the material being used, thereby enhancing the detailing and accuracy of engravings. This technological progression not only saves time but also maximizes resource utilization, resulting in superior final products.

Sustainable manufacturing practices in laser engraving are also gaining traction, driven by the need to reduce environmental impact. Newer energy-efficient laser engraver machines are designed to consume less power, and eco-friendly processes are being adopted to minimize waste. According to a study, implementing such machines can lead to up to a 30% reduction in energy usage and a significant decrease in operational waste output. These practices are crucial as manufacturers aim to meet environmental regulations and consumer demands for sustainable products while maintaining competitive quality and performance.

Benefits of Laser Engraving Machines in Modern Manufacturing

Laser engraving machines offer unparalleled precision and speed, making them indispensable in modern manufacturing. Unlike traditional engraving methods, laser engraving achieves accuracy to the micron level, significantly reducing error margins. For instance, while manual engraving may involve variations of up to 0.5 millimeters, laser technology can maintain consistency within 0.01 millimeters. This precision not only enhances the quality of the products but also accelerates production timelines, critical for industries where precision is paramount, like in aerospace and electronics.

The versatility of laser engraving is another significant advantage, as it can engrave a diverse range of materials including wood, metal, and plastic. This versatility allows the technology to be utilized across various industries; for example, in the automotive sector, it is used to engrave VIN numbers on metallic surfaces, whereas in the electronics industry it is instrumental in marking circuit boards. The adaptability of laser engraving machines to handle different substrates without the need for complex setup changes enhances their utility across manufacturing domains.

Cost-effectiveness and efficiency are further accentuated by laser engraving machines due to their ability to minimize material waste and increase production rates. Traditional methods often result in excessive material wastage and higher operational costs due to manual intervention and error correction. However, laser technology offers a cleaner cut and reduces waste substantially. As noted, some industries have reported up to a 50% reduction in material loss and a 30% increase in production speed, making laser engraving a financially viable option while enhancing production efficiency. This positions laser engraving machines as crucial components in the pursuit of optimized manufacturing processes.

Innovative Technologies Enhancing Laser Engraving

The field of laser engraving has seen significant advancements, particularly in fiber and CO2 laser technologies, which are transforming various engraving applications. Fiber lasers are renowned for their ability to engrave on metals with high speed and precision, making them ideal for industries like automotive and aerospace. In contrast, CO2 lasers excel in engraving non-metal materials such as wood and acrylic, utilized in signage and artistic designs. These different laser types allow manufacturers to select the most suitable technology based on material requirements and desired engraving outcomes.

Another technological leap is the integration of 3D printing with laser engraving. This combination offers new possibilities, enabling manufacturers to create complex three-dimensional objects with intricate surface engravings efficiently. For instance, the jewelry industry benefits from this integration, producing detailed designs with precision and reduced wastage. A growing trend in modern manufacturing, this hybrid approach is setting new standards for customization and innovation across sectors.

Ultrafast laser cutting technology represents another pivotal advancement in the manufacturing sector, offering potential revolutionary impacts. With the capability to deliver incredibly fast pulsed laser beams, ultrafast lasers achieve high precision cuts and engravings on materials previously considered difficult to process. Recent breakthroughs in this technology promise enhancements in speed, accuracy, and material flexibility, crucial for industries striving for efficiency and sophistication. These innovations, powered by laser engraving machines, are paving the way for a future of more versatile and efficient manufacturing solutions.

Key Industries Benefitting from Laser Engraving Machines

Laser engraving machines are revolutionizing several key industries by enhancing product quality and increasing precision. In the automotive manufacturing industry, laser engravers are essential for improving branding techniques and product quality. The precision of laser engraving allows manufacturers to permanently mark vehicle components for traceability and anti-theft purposes, thus adhering to strict industry standards and regulations. Recent advancements, such as the MarkStar Handheld VIN introduced by Laser Photonics Corporation, demonstrate the growing demand for these technologies in vehicle part marking, particularly for components like catalytic converters.

In the medical device production field, laser engraving plays a crucial role in ensuring that all products meet stringent health standards. It provides unparalleled precision, allowing manufacturers to engrave necessary markings on small and intricate devices without damaging them. This precision is vital for compliance with health regulations, as it aids in traceability and ensures that the products are safe for use in sensitive environments.

The jewelry and electronics industries greatly benefit from laser engraving by adding value through customization and branding. In jewelry, laser engraving allows for intricate designs and personalization, providing consumers with unique and bespoke pieces. Similarly, in electronics, this technology is used to engrave components with logos and serial numbers, ensuring brand identity and component traceability. With advancements in laser engraver machines, these industries are seeing enhanced capabilities in terms of detail and efficiency, thus creating high-quality and personalized products that stand out in the market.

Product Showcase: Advanced Laser Engraving Machines

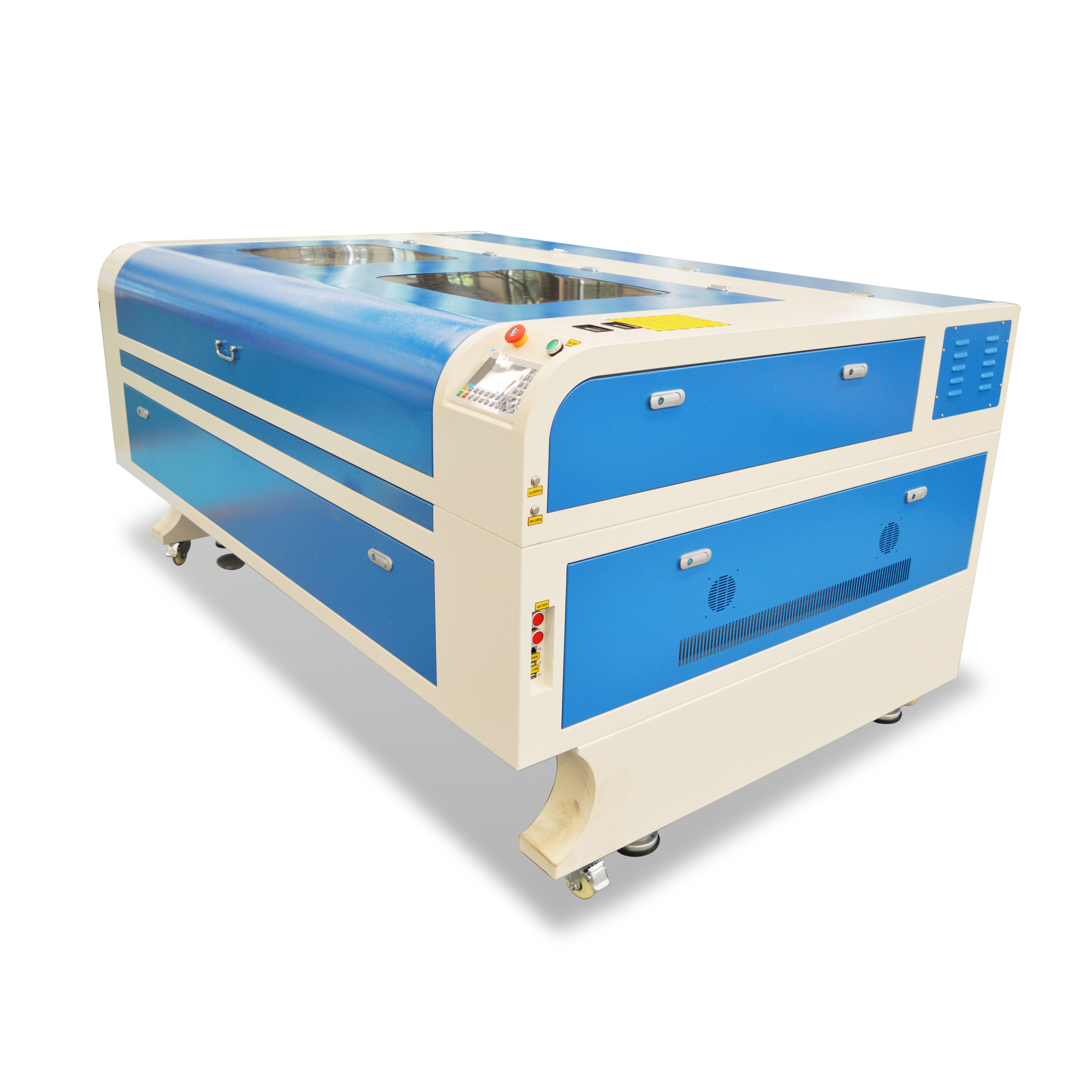

In today's competitive industrial landscape, laser engraving machines stand out as essential tools for precision engineering and artistic endeavors. The Laser Engraving and Cutting Machine 1530 is a prime example, equipped with 57 dual motor X-axis/Y-axis three wire 15 linear guide rails for enhanced speed and precision. It's particularly suitable for large-format projects, offering a working area of 1500x3000mm. From intricate designs to high-volume production, this machine is designed to handle a wide array of tasks efficiently. Laser Engraving and Cutting Machine 1530

The Laser Engraving and Cutting Machine 1610 offers advanced DSP control technology, optimizing cutting paths to enhance efficiency. It features dual laser heads that can be adjusted for different tasks, making it ideal for industry-level applications where diverse sheet metal processing is required. Its robust frame ensures stability and accuracy even at high speeds. Laser Engraving and Cutting Machine 1610

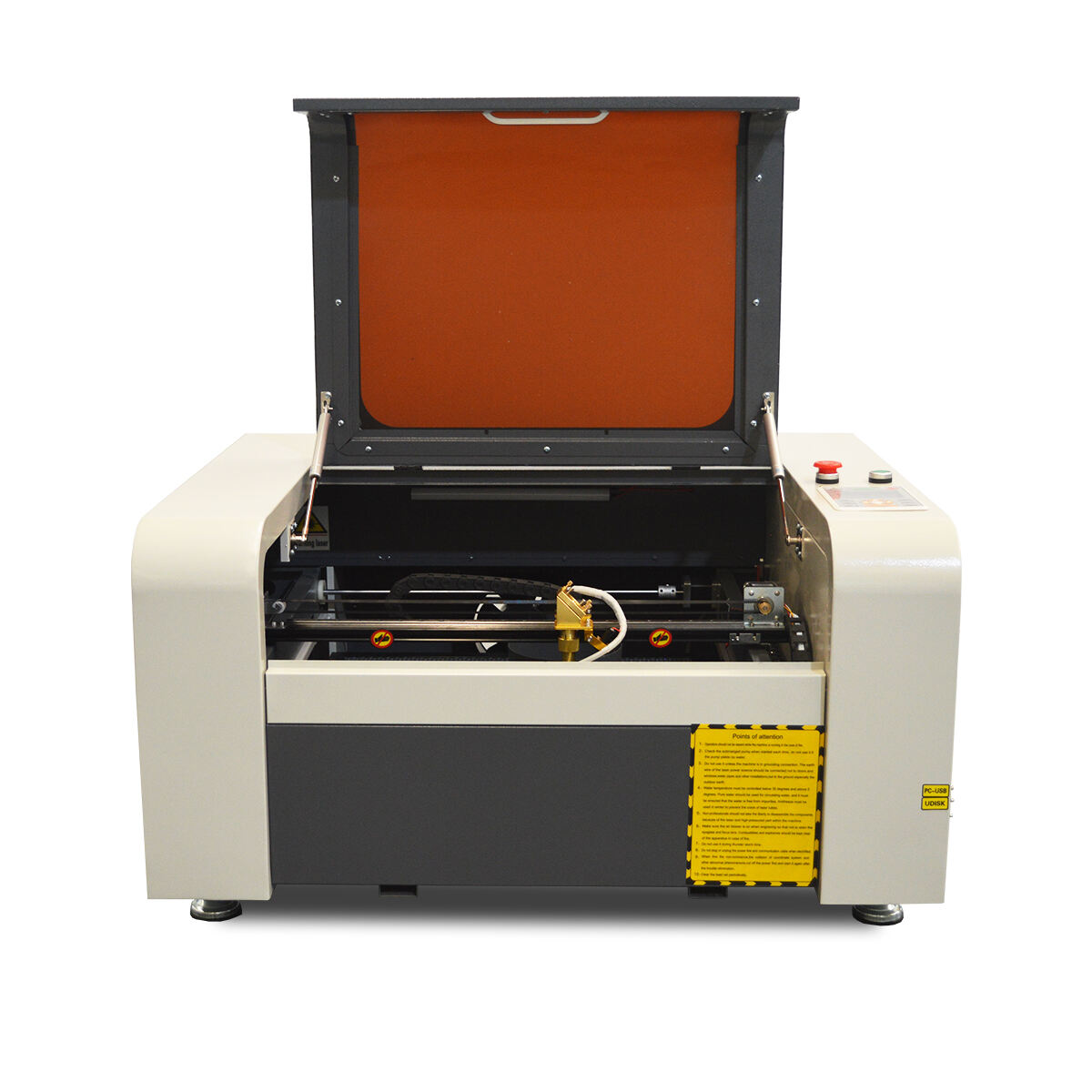

For those seeking outstanding performance and efficiency in intricate tasks, the Laser Engraving and Cutting Machine 4040 fits the bill. Its compact design and cellular lifting platform allow for precise operations, making it well-suited for high-precision engravings. This machine is ideal for small-scale tasks requiring meticulous attention to detail. Laser Engraving and Cutting Machine 4040

Lastly, the Laser Engraving and Cutting Machine 4060 is renowned for its innovative features and competitive market edge. With a focus on user convenience, this machine combines top-grade components and a robust build to facilitate complex engraving and cutting activities. Laser Engraving and Cutting Machine 4060