Exploring the Different Materials You Can Work with Using a Laser Engraving Machine

Introduction to Laser Engraving Materials

Understanding the basic principles of laser engraving is essential for achieving precise and high-quality results. Laser engraving involves using powerful lasers, such as CO2 and fiber lasers, to etch designs onto various materials. Each type of laser interacts differently with materials due to variations in wavelength and power. CO2 lasers are typically used for non-metallic materials like wood, acrylic, and glass, while fiber lasers are more suitable for metal engraving due to their ability to tackle hard surfaces.

Selecting the right materials for laser engraving plays a critical role in determining the quality, durability, and aesthetics of the final product. Materials must be chosen based on their compatibility with the laser type and the intended design. For example, wood offers a natural aesthetic, while acrylic provides clear and crisp engravings. Meanwhile, metals, depending on the alloy, can produce intricate details for durable applications. By carefully choosing materials, you can ensure that the engraved product not only meets your design expectations but also withstands the test of time.

Common Laser Engraving Materials

When it comes to laser engraving, wood stands out as a highly versatile medium used in a wide array of applications from crafts to home decor. Wood's natural engravability allows creators to produce stunning photo-engravings, detailed inlays, and sophisticated decoration pieces with ease. For instance, high-quality wood types like maple, cherry, and walnut are preferred for premium products due to their durability and aesthetic appeal. On the other hand, plywood and MDF are more cost-effective options for mass production projects, providing a balance between quality and affordability.

Acrylic is another popular choice for laser engraving, celebrated for its ability to produce clean finishes and a wide range of colors. Its unique properties allow for different textures, such as frosting or multicolor effects, making it ideal for creating vibrant signage and eye-catching displays. The ability of acrylic to deliver precise and consistent results every time makes it a reliable material for businesses looking to create professional and appealing products.

Leather offers a unique opportunity for personalized and luxurious laser engraved products, such as wallets and belts. Using laser engraving, intricate details can be added to leather goods, enhancing their elegance and uniqueness. Successful projects often utilize vegetable-tanned or natural leather to maintain both quality and safety, as synthetic leather can be unsafe and less enduring when engraved.

Metals, like aluminum and stainless steel, are prized for their durability and the professional finish they lend to any engraved product. Laser engraving on metals is commonly used for brand markings and durable designs that last. Aluminum 6061, known for its strength and corrosion resistance, and Brass H62, noted for its beauty and malleability, exemplify how laser engraving elevates metal products' usability and aesthetic.

Plastics are widely used in laser engraving due to their cost-effectiveness and versatility, especially for projects requiring prototypes or customized gifts. A variety of plastic materials can be engraved, though caution is recommended with materials like PVC due to potential toxic fumes. High-quality plastics such as acrylic are preferred for ensuring safety and durability.

Fabric materials, including cotton and felt, also offer creative possibilities with laser engraving. Engraved fabrics are used for custom clothing and home textiles, providing unique designs that stand out. The laser engraving process strengthens fabric designs by preventing fraying, making it a growing trend in the fashion industry.

Finally, paper and cardboard present economical options for laser engraving, often used in crafts and prototypes. These materials are excellent for creating custom packaging or intricate invitations, offering a cost-effective solution with aesthetically pleasing results when engraved properly.

Each of these materials exhibits unique properties that make them suitable for specific applications, and understanding these can help you choose the best material for your laser engraving projects.

Factors to Consider When Choosing Laser Engraving Materials

When selecting laser engraving materials, the type of laser engraver you use is crucial. CO2 lasers are ideal for non-metal materials like wood, acrylic, and leather due to their longer wavelengths, which allow for precise and effective engravings. In contrast, fiber lasers, with shorter wavelengths, excel at engraving metals such as aluminum and stainless steel, thanks to their high intensity and minimal reflection issues. Choosing the appropriate laser type ensures that you achieve optimal results without compromising the material or the equipment.

The desired finish and depth of the engraving significantly influence material choice. For instance, deep engravings might necessitate using materials like hardwood or certain metals that can withstand extensive processing. On the other hand, materials such as acrylic or fabric are suitable for surface markings or intricate designs, offering clean finishes and sharp details. Understanding the project's requirements for finish and depth can guide the selection process to achieve the best aesthetic and functional outcomes.

Material thickness and durability are also important considerations. Thicker materials often require more powerful lasers to achieve precise engravings, which can affect engraving speed and overall quality. For instance, thicker wood or metal might necessitate a slower engraving speed to ensure detailed designs without damaging the material. Conversely, thinner materials like paper or cardstock are more suitable for quick and efficient engravings. By choosing the right material thickness, you can balance the engraving speed and quality, ensuring durable and visually appealing results.

Debunking Common Myths about Laser Engraving Materials

Misconceptions abound when it comes to laser engraving with fiber lasers, especially regarding organic materials. Many believe that fiber lasers are unsuitable for organic materials. However, experts assert that these lasers can effectively engrave certain organic substances with precision and efficiency. Materials such as wood and leather can be engraved using fiber lasers when appropriate settings are applied. This demonstrates the versatility of fiber lasers beyond metals, expanding the possibilities in creative and industrial applications.

Safety concerns often arise around engraving plastics with lasers, mainly due to harmful fumes. While it is true that certain plastics, when laser engraved, can release toxic emissions, Safety Data Sheets (SDS) offer essential guidance on handling these materials safely. Engravers are advised to use ventilation systems and select plastic types with minimal emission risks. Understanding these safety factors allows for a safer engraving process without compromising on material variety.

Metal engraving is another area rife with myths, particularly the notion that only select metals can be engraved. In reality, numerous metals can be processed using laser engraving. Techniques vary, such as using CO2 lasers for softer metals like aluminum and fiber lasers for harder metals, including stainless steel. This flexibility in laser technology demonstrates that metal choice is less restricted than commonly perceived, allowing a broader scope for creative and industrial engraving projects.

Recommended Materials for Specific Projects

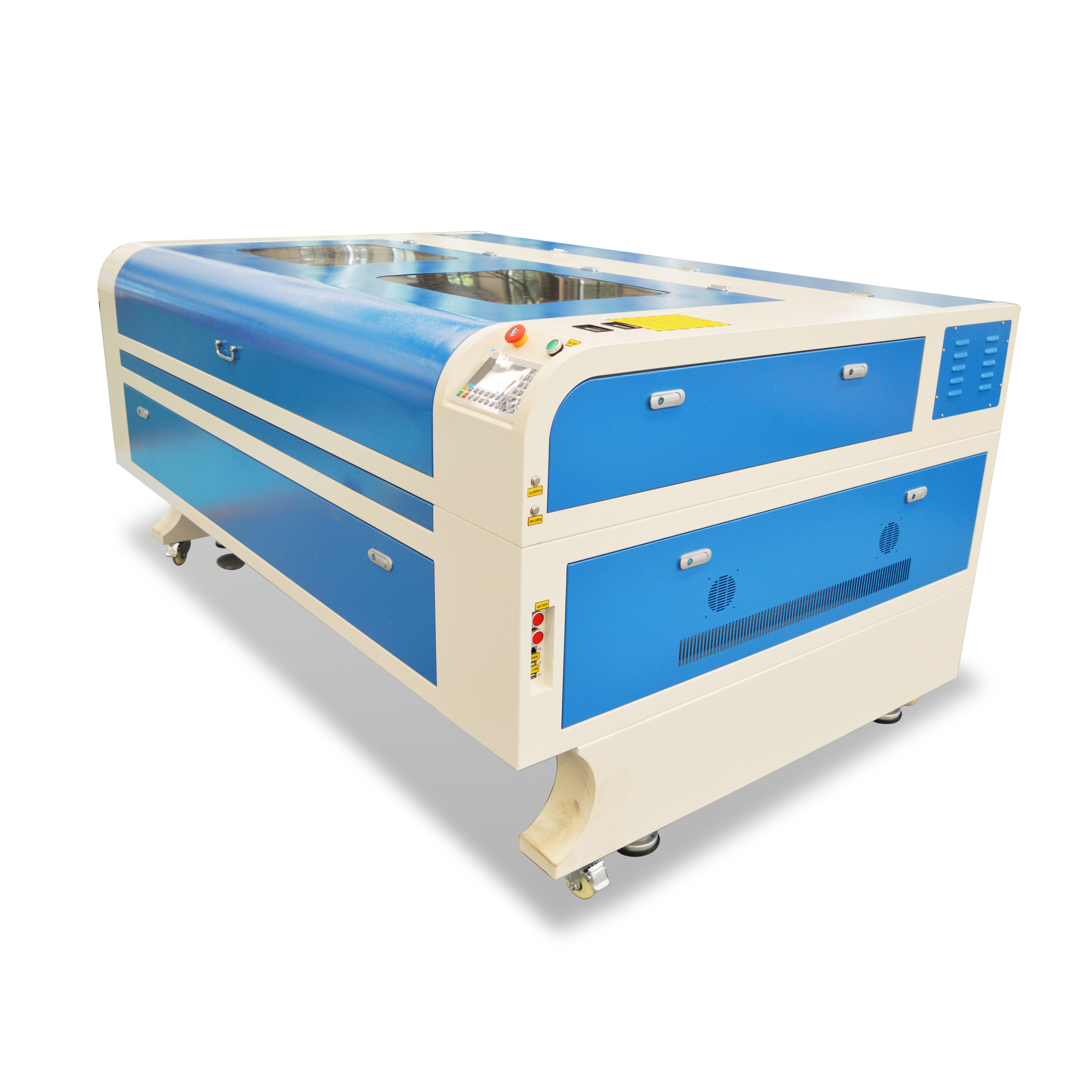

Selecting the appropriate material for specific laser engraving and cutting machines can significantly impact the quality and precision of the final output. For the Laser Engraving and Cutting Machine 1610, utilizing durable materials like wood and acrylic is ideal for consistent results. These materials complement the machine's capabilities in precise and efficient large-format projects.

For a Cabinet Type Laser Marking Machine, materials requiring high precision such as metals like aluminum and brass are excellent. These materials withstand the marking process and maintain a clear and concise finish, crucial for industrial applications.

A Desktop Laser Marking Machine is particularly suitable for small-scale projects with materials like plastics and leather. Its compact design offers the flexibility needed for detailed tasks without compromising on the speed or quality of marking.

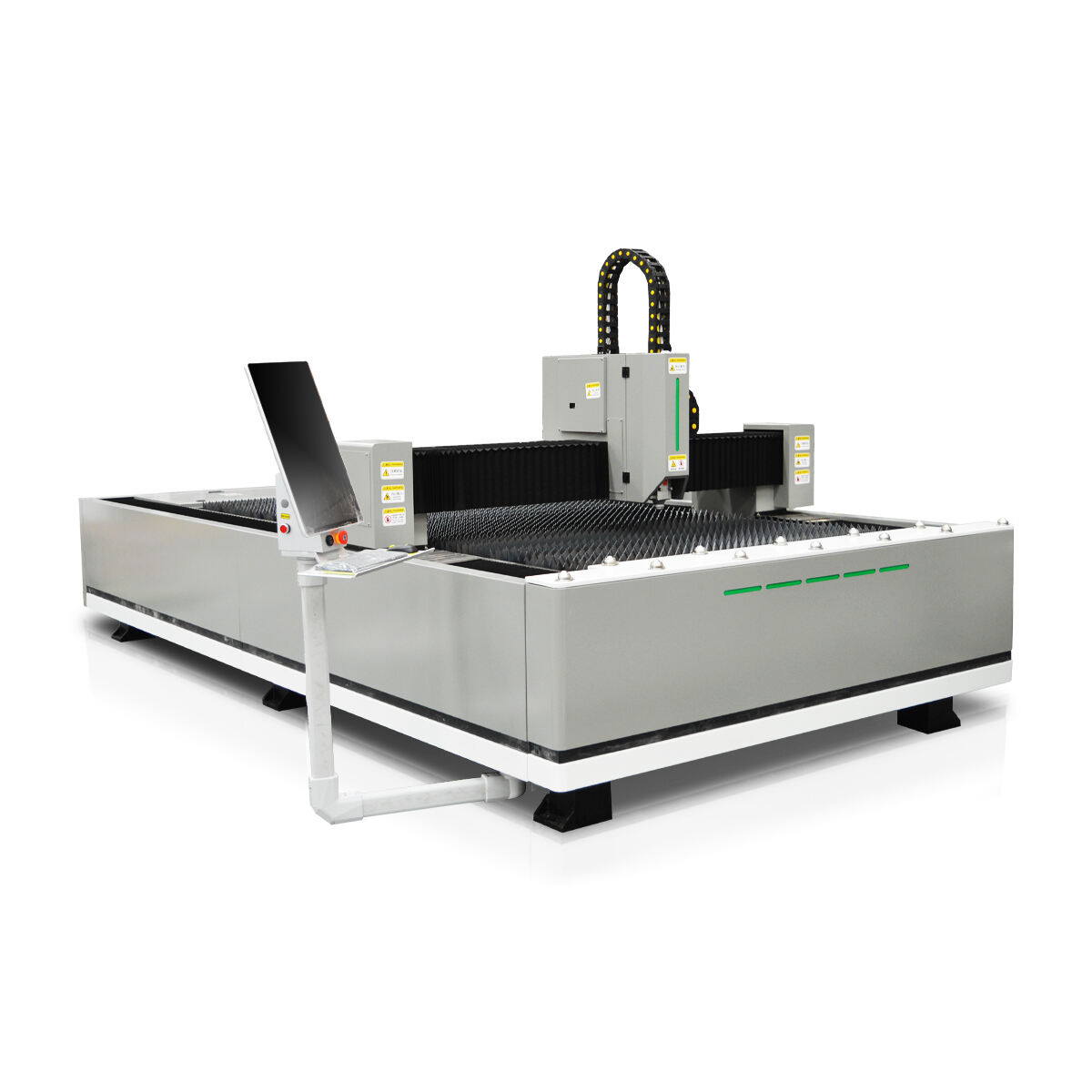

For the Fiber Laser Cutting Machine 1530, metal sheets such as stainless steel and carbon steel are optimal. These materials take advantage of the machine's powerful laser, precision, and speed to deliver clean cuts and high throughput for industrial applications.

Lastly, the Portable Laser Marking Machine is excellent for mobile projects demanding speed and convenience. It is suitable for materials like plastic and aluminum, balancing portability with efficient and clear imaging.

Tips for Successfully Working with Laser Engraving Materials

Before diving into high-volume engravings, it is crucial to test material compatibility. This step ensures that the chosen material can withstand the laser engraving process without compromising quality. By conducting preliminary tests, you can avoid wasting resources and ensure the final product meets your expectations.

Adjusting laser settings such as speed, power, and frequency according to the material being used is vital for achieving optimal results. Different materials react differently to laser beams, requiring specific settings to ensure precision and quality. For example, softer materials may require lower power settings to prevent burning, while harder materials might need higher power and slower speeds.

Maintaining a clean workspace is essential to prevent contamination that can affect engraving quality. Dust and residue can interfere with the laser's operation and result in uneven engravings. By keeping the workspace tidy and free from debris, you can ensure that each engraving is as precise and clean as possible.

Conclusion: Unlocking Your Creative Potential through Material Choice

Exploring various materials is the key to unlocking new techniques and styles in laser engraving, which can significantly enhance your creativity and skills. By experimenting with different materials, such as wood, acrylic, leather, metals, and plastics, you allow yourself to discover unique properties and effects that can lead to more innovative designs. Each material offers its potential for distinct patterns and finishes, encouraging you to push the boundaries of your creativity.

As the laser engraving industry evolves, we can anticipate exciting innovations and advancements in materials. Future trends may include the development of eco-friendly materials or advanced composites that offer improved durability and aesthetics. Staying updated on these advancements not only keeps you at the forefront of your craft but also opens doors to new possibilities and applications in laser engraving.